PRODUCTION AND REGENERATION

TOOLROOM is equipped with modern machine park that can meet the

very diverse and demanding tasks.

The machines are operated by experienced professionals

having many years of experience in material processing.

With the help of technology listed in below in this article we can make for you a whole range of complex tools and items/machine components. When it comes to our activity, we perform on the basis of our own or entrusted documentation:

- Punching dies and stamping dies with both manual and progressive support to work automatically

- Injection molds for plastics

- Pressure casting die for aluminum alloys

- Other equipment including equipment for drilling, milling, turning, welding and checking

- Spare parts/replacement parts to the above mentioned tools and other devices, punches, dies, cores, inserts, etc.

In addition, we offer services:

- regeneration of molds and stamping dies

- Turning on lathes controlled numerically and conventionally (also mass production)

- milling on CNC milling centers and tool milling

- grinding of surfaces, shafts and holes

- making holes of any shape with the wire cutting machines controlled in 4 axes

- EDM subtracting (plunge)

In the tool production process, we use integrated CAD/CAM program working with 3D machining centers

LATHING

We perform this type of treatment mostly on our two numerically controlled lathes. Parameters and possibilities are listed in the descriptions of specific machines. We are interested in working in the field of manufacturing of smaller and larger series. We also have a conventional lathe for rough, individual part production.

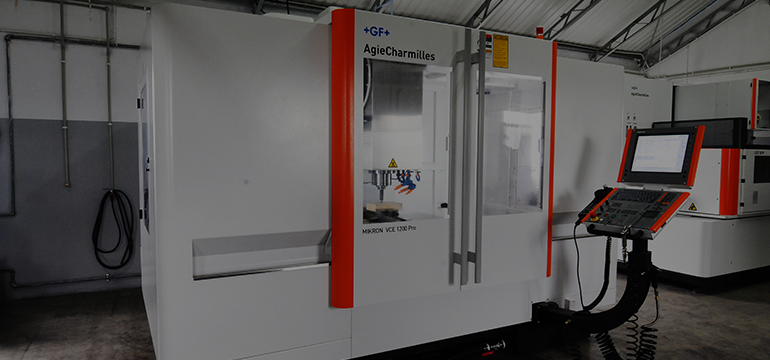

MILLING

Our strength are our processing possibilities on the CNC-milling processing centers controlled in 3 axes. We are able to process machine parts with dimensions in excess of 1200 x 600 mm and up to 1200 kg. We own two such centers. Thanks to a very good technical condition of these machines the processing is carried out with high accuracy. We conduct rough milling by the conventional milling machines.

GRINDING TOOL

Without machines to perform this kind of processing no self-sufficient toolroom could exist, which is why we have a surface grinder, tool grinder (also called grinder) and shaft/holes grinder. This type of processing has often a huge impact on the quality of the fit of the parts and, hence, the quality of the tools.

ELECTROEROSIVE PROCESSING EDM/WEDM

We own two wire cutting machines (WIRE EDM) to perform punches, dies, cores and liners of any shapes up to 350 mm. This type of treatment is done with a very high accuracy where tolerance is few micrometers. EDM process also allows processing of hardened materials, where other methods in this field are often impossible. Wire cutting machines are indispensable in the production of cutting tools, but also other tools

The second type of processing in this technology is the drill plunge. The shape of the electrode (copper or graphite) is reconstructed by the use of the phenomenon of erosion in matrices with very high accuracy. This applies mainly for the production of injection molds. We own an EDM center, where it is possible to manipulate dies of maximum dimensions of 1000 x 700 x 400 mm.